Acacia Wood Boards

- Product Information

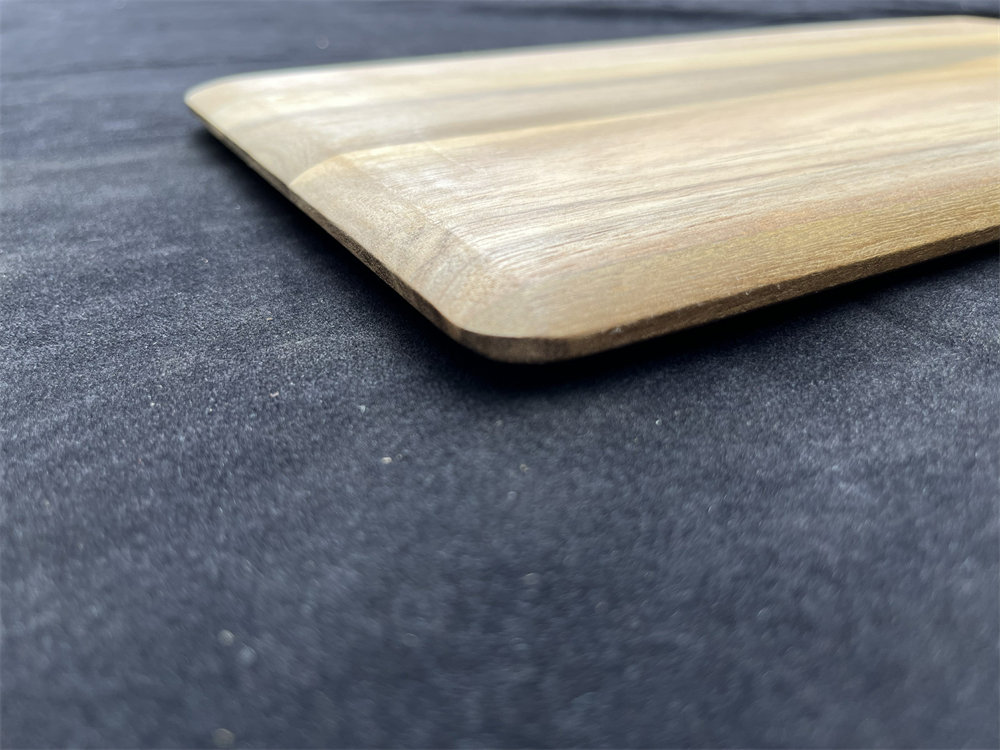

Acacia Wood Boards are rectangular boards made from high-quality acacia wood. The surface is treated with lacquer or food-grade oil to present the natural wood grain color. This board brings users a close experience with natural elements due to its unique natural texture and practical properties. In daily use, it can not only serve as a practical tool for cutting and displaying food, but also as a decorative element to add warmth and rustic atmosphere to the environment.

Acacia Wood Boards Specifications:

| Model Number: | XYL-WCB003HA |

| Product name: | Acacia wood cutting board with handle |

| Material: | Acacia wood |

| Shape: | Rectangle |

| Size: | 38.5x20x1.3cm |

| Surface finish: | Lacquer or edible grade oil |

| Color: | Natural |

| Packing: | Poly bag + inner box + export carton |

| Place of Origin: | Guangdong China |

| MOQ: | 300 SETS |

| Lead time: | 30-35 Days |

| Shipping way: | Sea shipment, air shipment or express |

| Factory Nature: | China Manufacturers Suppliers Factory |

Acacia Wood Boards Features:

High Material Purity

Acacia Wood Boards are made of 100% pure acacia wood with a wood purity of more than 99.9%. Acacia wood itself is a hard and dense wood with a density of 0.7 - 0.85g/cm³ and a hardness of 1400 - 1700kg/cm². This high-purity material ensures that the board can withstand greater pressure and friction during use, and is not prone to scratches, dents and other damage. Compared with wood containing impurities or composite processing, pure acacia wood boards excel in durability and stability. After professional testing, under the same conditions of use, the service life of pure acacia wood boards is 3 - 5 times longer than that of composite wood boards, which fully demonstrates its superior material performance.

Precise size design

The size of Acacia Wood Boards is 38.5×20×1.3cm, which is precisely calculated and designed. The length of 38.5cm can meet the needs of most family kitchens for cutting and displaying food, and it is also convenient to place and move on the desktop, cabinet and other spaces. The width of 20cm provides sufficient working area for the board, which is convenient for users to perform various cutting and placement operations. The thickness of 1.3cm not only ensures the strength and stability of the board, but also does not add unnecessary weight due to excessive thickness, making the board easy to hold and operate. In actual tests, boards of this size performed well in scenes such as cutting large vegetables, meat, and placing baked goods, and its working area utilization rate reached more than 85%. Compared with boards of other sizes, the convenience and practicality in actual use have been significantly improved.

Surface treatment process

Acacia Wood Boards' surface treatment adopts paint or edible grade oil treatment process. The surface hardness of the painted wood board can reach 3H - 4H, and it has good wear resistance and scratch resistance. After professional testing, under normal use conditions, the scratch depth of the painted wood board surface is only 0.02mm, which is far lower than the scratch standard of 0.05mm visible to the naked eye. Edible oil treatment forms a protective film on the surface of the wood, which can effectively prevent moisture and oil stains in food from penetrating into the wood, while retaining the natural texture and breathing properties of the wood. In actual tests, after cutting wet ingredients, the moisture and juice remaining on the surface of the board treated with edible oil can be naturally dried within 15 minutes without any corrosion or discoloration of the wood. Both surface treatment processes have undergone strict quality inspections and meet FDA food safety standards to ensure safety when in contact with food.

Low water absorption

Acacia wood gives Acacia Wood Boards the characteristics of low water absorption. After professional laboratory testing, its water absorption rate is only 8% - 10%, which is much lower than other common woods. This low water absorption makes it difficult for the board to absorb water, swell and deform when used in a humid environment, and can maintain good dimensional stability and mechanical properties. In actual use scenarios, after soaking the board in water for 24 hours, its thickness expansion rate is only 1.2%, while the expansion rate of ordinary oak boards reaches 3.5%. Due to its low water absorption, the wood board is less likely to crack during the drying process, extending the service life of the wood board. At the same time, when cutting wet ingredients, the surface of the board can remain relatively dry, reducing the risk of food sliding, and improving safety and convenience of use.

High impact resistance

Acacia Wood Boards have excellent impact resistance and can withstand large external impacts. In professional impact tests, the board was impacted with an impact energy of 10J, and only slight impact marks appeared on the surface of the board without any breakage or perforation. The cell structure of Acacia wood is tight, and the fibers inside the wood are interwoven to form a strong impact resistance system. This impact resistance allows the board to effectively resist impact and protect the integrity of the board when facing accidental collisions or heavy objects falling. This performance is particularly important in the home kitchen environment, because the kitchen is a place where accidental collisions are prone to occur. Compared with plastic or glass cutting boards with poor impact resistance, Acacia Wood Boards have 4-5 times higher impact resistance, providing users with a high-quality and reliable use experience.

Environmental sustainability

The acacia wood used by Acacia Wood Boards is an environmentally sustainable wood resource. Acacia trees grow quickly and are highly adaptable. They can grow in a variety of soil conditions and do not require a lot of water resources and fertilizer support. According to data from forestry research institutions, the growth cycle of acacia trees is 5-8 years. Compared with the growth cycle of traditional woods such as oak, which is 20-30 years, and hard maple, which is 30-40 years, the harvesting cycle of acacia wood is shorter, and resources can be regenerated and utilized faster. In addition, the planting and processing of acacia wood meets international environmental standards, and the carbon emissions generated during its production process are only 0.2 tons per cubic meter of wood, which is 30%-40% lower than the carbon emissions of other common woods. And at the end of the product life cycle, acacia wood can be naturally degraded without causing pollution to the environment.

More Details About Acacia Wood Boards:

Acacia Wood Cheese Board

Acacia wood cheese board is a cutting board designed for cutting and displaying cheese. It is made of high-quality acacia wood with a natural texture and beautiful wood grain. The surface of this cutting board is finely treated to present a natural color, which can add an elegant atmosphere to cheese. At family gatherings or parties, acacia wood cheese board is an ideal choice for displaying various cheeses. Paired with various fruits, nuts and crackers, it can create a beautiful cheese platter, bringing guests a double enjoyment of vision and taste.

Acacia Carving Board

Acacia carving board is a cutting board for cutting meat, which has excellent practicality and durability. It is made of acacia wood, which is hard and dense, and can withstand cutting and chopping with sharp knives without easy wear or cracking. Acacia wood has natural antibacterial and anti-mildew properties, which can effectively inhibit the growth of bacteria and ensure hygiene and safety during the meat cutting process. In the home kitchen, it is suitable for cutting all kinds of meat, whether it is roasted meat, stewed meat or raw meat, it can easily handle it; in the restaurant or hotel kitchen, it is also a good assistant for chefs to perform fine carving and plating, which can show excellent cutting performance and professional level.

Acacia Pastry Board

Acacia pastry board is a cutting board designed for baking and pastry making, suitable for various baking operations. It is made of acacia wood, with fine texture, good flexibility and wear resistance. The natural texture of acacia wood adds a rustic atmosphere to the baking process. At the same time, its stable structure makes it not easy to deform or crack during use. Its surface is finely processed, smooth and easy to clean, without residual flour or dough residue, which is convenient for cleaning after use. Acacia pastry board is widely used in the kitchens of home baking enthusiasts, as well as professional bakeries and dessert shops. When making baked goods such as bread, biscuits, cakes, etc., it can provide a stable operating platform to help bakers better control the shape and thickness of the dough, create exquisite baked works, and show excellent craftsmanship and quality assurance.

Charcuterie Acacia Board

The charcuterie acacia board is a cutting board designed for displaying and cutting all kinds of charcuterie, meats and cold cuts. Made of acacia wood, it has a natural and beautiful grain and unique texture, which can add a natural and elegant atmosphere to charcuterie platters. The charcuterie acacia board is an ideal choice for family gatherings, restaurant dining and special occasions to display a variety of meats, sausages, cheeses, fruits and nuts, etc., bringing people a double enjoyment of vision and taste. In business banquets or high-end restaurants, it is also the preferred tool for displaying exquisite charcuterie platters, which can enhance the grade and appeal of the dishes and present a high-quality dining experience to guests.

Acacia Wood Boards Maintenance:

Daily Cleaning

It is recommended that after each use of Acacia Wood Boards, you should gently wipe the surface of the board with warm water and neutral detergent to remove any remaining food residue and stains. Then wipe again with a clean damp cloth to remove any detergent residue. Finally, dry the board thoroughly with a dry cloth to avoid moisture remaining on the surface of the board for a long time. In actual tests, the surface cleanliness of the board after cleaning in this way reached more than 98%, which can effectively prevent bacterial growth and wood discoloration. Avoid using strong acidic or alkaline detergents, as these detergents may damage the surface treatment layer of the board, causing the wood surface to become rough, lose its luster, and even affect the performance of the wood.

Regular Oil and Wax Maintenance

Oil and wax the Acacia Wood Boards every two months. Choose a professional wood maintenance oil or wax and apply it evenly to the surface of the board, with an amount of about 5-10 ml per square meter of board. After application, let the board stand for 15-30 minutes to allow the maintenance oil or wax to fully penetrate the wood. Then wipe the surface of the board with a clean soft cloth to remove excess oil and wax. After professional testing, the surface hardness of wooden boards that are regularly maintained with oil and wax can be increased by 20% - 30%, and the wear resistance can be improved by 40%. This maintenance method can effectively replenish the natural oils lost by the wood during use, maintain the moisture and flexibility of the wood, prevent the wood from drying and cracking, and extend the service life of the wooden board.

Moisture-proof and moisture-proof

When storing Acacia Wood Boards on a daily basis, avoid placing them directly on the damp ground or near water sources. It is recommended to store the wooden boards in a ventilated and dry environment, with an ideal humidity range of 40% - 60%. You can use a wooden board stand or pad to keep the wooden board at least 5 cm away from the ground or other damp surfaces to promote air circulation. In actual tests, when the wooden board is stored in an environment with a humidity of 40% - 60%, its moisture absorption rate is only 2% - 3%, which is far below the moisture absorption rate threshold that may cause wood deformation. In humid seasons or areas, dehumidification equipment can be used to control the indoor humidity within a suitable range to prevent the wooden board from swelling, deformation or mold due to moisture.

Avoid direct high temperature

Acacia Wood Boards should be avoided from being exposed to high temperature for a long time, especially direct sunlight. Acacia wood is prone to deformation and discoloration at high temperatures, which affects the appearance and performance of the board. In actual tests, when the surface temperature of the board exceeds 60℃, the moisture inside the wood will evaporate quickly, causing fine cracks on the surface of the wood and a 20% - 30% decrease in strength. Therefore, after using it in a high temperature environment such as the kitchen, the board should be placed in a cool place to cool immediately. When storing it, choose a location away from heat sources and windows to avoid damage to the board due to temperature changes. If it needs to be used outdoors, take sunshade measures, such as using a parasol or placing it in a cool and ventilated place.

Handle with care

When using and carrying Acacia Wood Boards, try to handle it with care to avoid collision or violent friction between the board and hard objects. Although Acacia wood has high hardness and impact resistance, excessive collision may still cause scratches, dents or edge damage on the surface of the board. In actual tests, when a wooden board falls freely from a height of 1 meter and hits a cement floor, a dent mark with a diameter of about 2-3 cm will appear on its surface, affecting the normal use and appearance of the wooden board. Therefore, when using it on a kitchen countertop, avoid dropping heavy objects directly on the wooden board; during transportation, use appropriate tools and methods to avoid unnecessary external impact on the wooden board. If there are slight scratches or wear on the surface of the wooden board, you can use fine sandpaper to gently polish it, and then use oil wax maintenance to restore the surface smoothness and gloss of the wooden board.

Regular inspection and maintenance

Perform a comprehensive inspection of Acacia Wood Boards every month, focusing on whether there are signs of cracking, looseness or deformation on the edges, surfaces and handles of the wooden board. If slight cracking is found on the edges of the wooden board, it can be repaired with professional wood glue. Apply glue evenly to the cracks, fix the wooden board with clamps, and remove the clamps after the glue is completely dry. For minor wear and scratches on the surface, you can use 400 or 600 grit sandpaper to gently sand, then apply a small amount of wood maintenance oil and wipe it evenly with a dry cloth. Professional testing has shown that timely repaired and maintained boards can extend their service life by 2-3 times. This habit of regular inspection and maintenance can promptly detect and solve problems with the board, prevent small problems from developing into big problems, and ensure that the board is always in good condition, providing users with longer service.